“Growers rarely believes that water ruining water rule of biophilms, systems, and pipelines that include microorganisms, sediments and organic compounds.” This biofilm is caused by blockages, reduces irrigation uniformity and It promotes the biological corrosion process that shortens the useful life of the irrigation system. Installation of water disinfection system for agriculture is not only a healthy measure, but it is also an investment in the sustainability of channels and pipes.

© JH Hydroponic System Sl

© JH Hydroponic System Sl

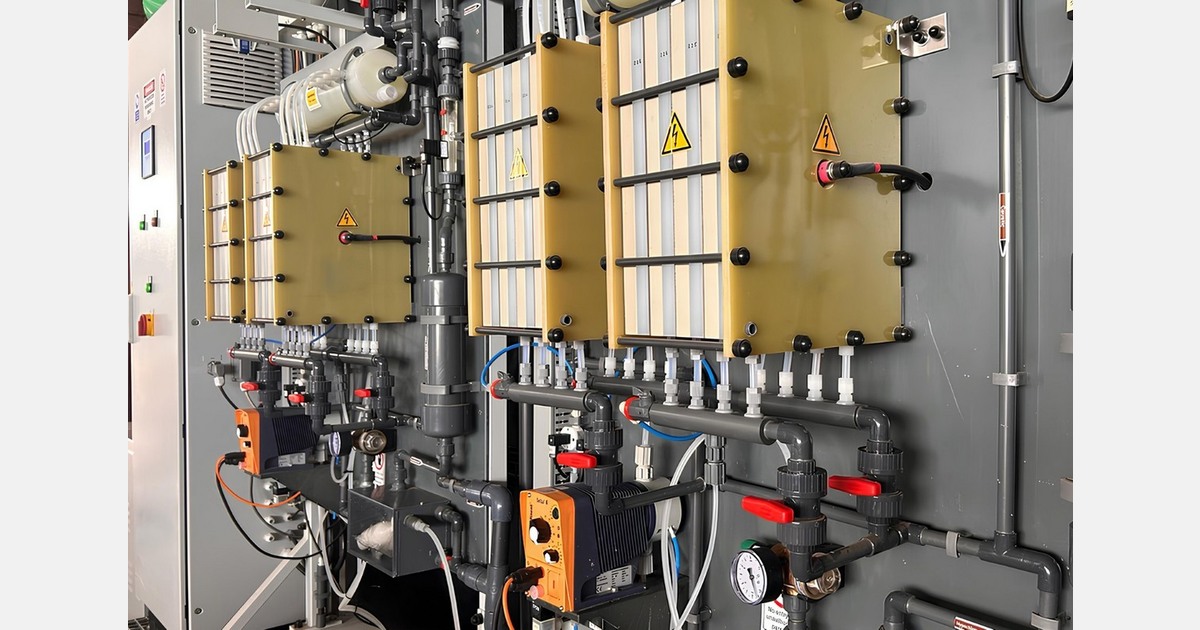

The empty hypocloric acid (PHA) is a wide disinfectant spectrum, which can be created at low operating cost. Biofilms and pathogens are very effective, such as bacteria, fungi and algae, which can cause plant diseases. PHA also improves root health, it supports environmental disinfection in seed work, and does not disinfect the materials when applied to proper parameters. Unlike aggressive chemicals, it does not degrade plastics and metals. In addition, PHA allows a continuous and controlled generation, which is suitable for treating 24/7 on recirculation systems. It is compatible with organic cultivation.

Due to these features, Pha-based systems are particularly suitable without weakening materials to protect the channels, tubes and drops lines. PHA prevents the formation and dissemination of biofilms, which cause particles to block traps and drops and nozzles. Keeping internal surfaces clean, microbial vacuums minimize, reducing friction and localized corrosion. This helps maintain stable flow rate and irrigation uniformity, it is essential to prevent water stress and inconsistencies in crop production.

© JH Hydroponic System Sl

© JH Hydroponic System Sl

The use of PHA also reduces the need for physical interventions, such as mechanical cleaning, aggressive emptying or replacement of pipes or channels. When the cooling systems of climate, pad and fans are common, PHA expands the wet parts service that provides a practical solution that farmers improve the sustainability of the system and reduce maintenance costs.

In comparison to some PHA disinfection solutions, each method presents advantages and limits according to the need for water quality and facilities. The commercial chlorine and hypoclorito are effective, but chlorinated on products can cause crop toxic and corrosive for plastics and stamps. Ultraviolet (UV) treatment works as preserved, but it does not remove biofilms attached to surfaces or with sediment in open circuits effectively. If the pipes are already infected, UV treated water has been turned on again. UV has filtered water filtered, clarified. Although peroxides, although they are useful as oxidizers, they offer mainly oxygenation. In the recommended doses, their oxidation power is limited and in higher doses, biofilm layers can distinguish those drops, reappearing biofilms again.

On the contrary, Phak is effective against biofilm, it can be created on a network, which is constant follow-up, has a lower impact on materials when properly dosed and is compatible with the beneficial treatments for microorganism. For recirculation, external networks, and with the observed criminals, Pha offers a balanced solution between efficiency and protection of infrastructure.

© JH Hydroponic System Sl

© JH Hydroponic System Sl

Where is it especially installing a PHA system?

Installation of a PHA system is especially recommended to be recommended in greenhouses that recreating drain, where the risk of pathogen and biophilm. It is also suitable for high density crops, such as strawberries, cherry tomatoes or peppers, where critical waters are critical for coherent benefits. The farms with repetitive screen or replacement of guardian substitutes also take advantage of the pH, as it reduces the early replacements of metal or plastic criminals.

A required PHA system decreases mechanical cleaning and intensive chemical cleaning, remote tracking through automatic facilities adapted to each installation. This approach reduces labor costs, reduces the frequency of production and reduces the spare rate of the pipes and cardboards. In many cases, trading facilities get payment within a series of production cycles, although the detailed dose and system design should be based on the technical analysis of the water and irrigation network.

© JH Hydroponic System Sl

© JH Hydroponic System Sl

As a result, irrigation water disinfecting is not a hygiene measure, it is a strategy to protect agricultural infrastructure. By avoiding biofilm formation and corrosion, gutter and pipe systems maintain their performance for a long time, reducing maintenance costs and extending service life. In open areas, greenhouses and tunnels for valuable crop breeders, a PHA system helps to ensure consistent irrigation, health and long-term profitability. Locks, corrosions or early replacements of irrigation systems may benefit this solution.

Cannabis News5 months ago

Cannabis News5 months ago

Florida6 months ago

Florida6 months ago

Canadian Cannabis News6 months ago

Canadian Cannabis News6 months ago

Best Practices6 months ago

Best Practices6 months ago

Video6 months ago

Video6 months ago

Video6 months ago

Video6 months ago

Video5 months ago

Video5 months ago

aawh6 months ago

aawh6 months ago